Premium Custom Semiconductor Cables for Continuous Flexing

Custom semiconductor cables designed by leading North American provider of custom cables explicitly tailored to your requirements.

Critical Advantages of Custom Semiconductor Cables

Custom cables for semiconductor equipment requires limited space with tight bend radii and low friction. BizLink elocab designs Custom Flat Cable that features up to 150 million flex cycles, self-supporting, low outgassing for vacuum environments, and low particulate for ISO class 1 cleanroom.

Our Custom Flat Cable and Custom Round Cable made in North America are available in bulk or as a co-development and turn-key assembly solution.

• Laminated and hybrid designs, custom components

• Complete cable assemblies and prototype orders

• Etching equipment, flat panel displays, wafer handling, and robotics

• Laser cutting and laser edging machines

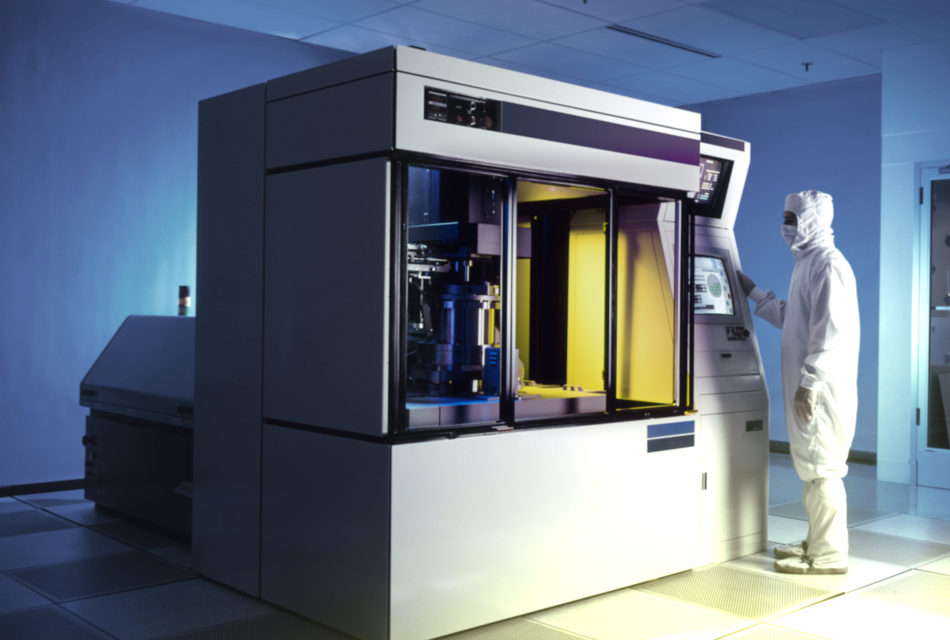

• Advanced lithography, wafer processing, and inspection

Applications for Custom Semiconductor Cables

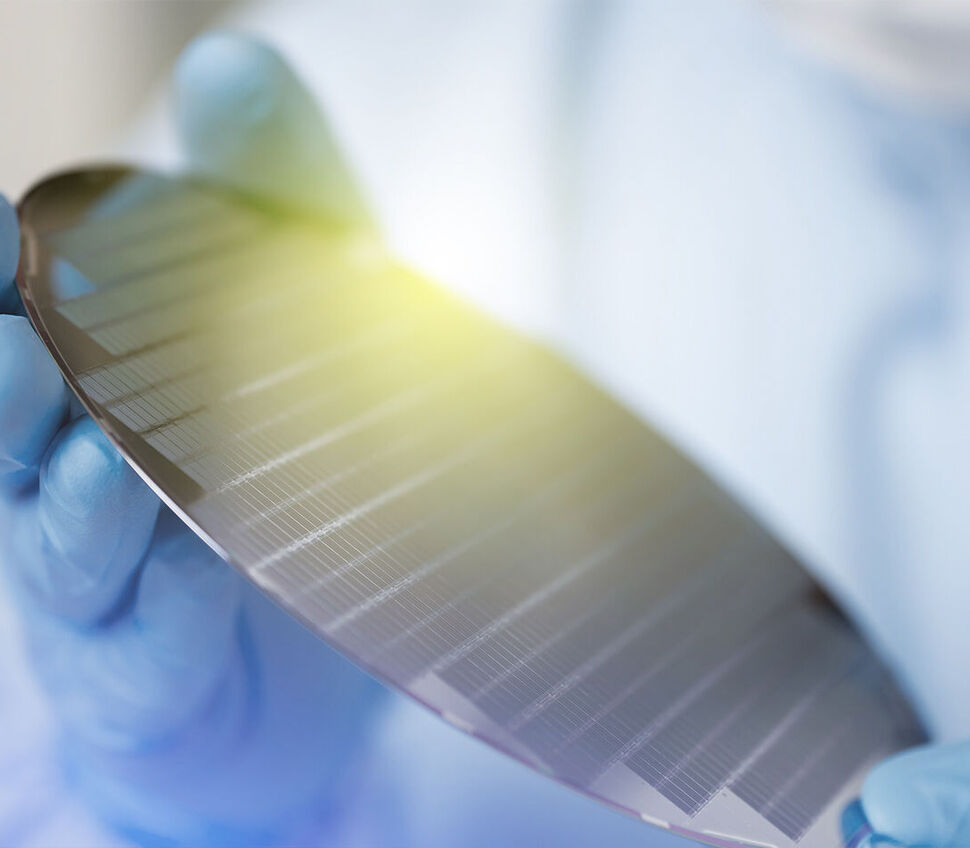

Wafer Handling & Robotics

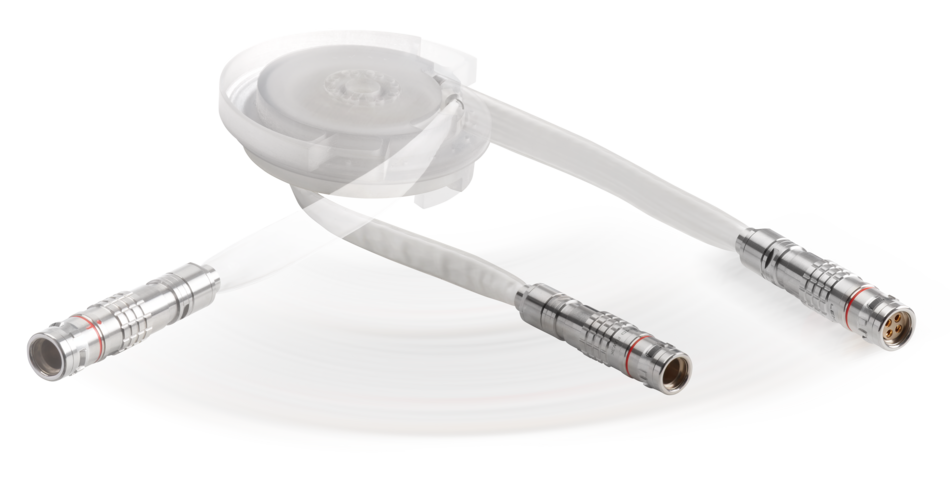

- Proprietary Clock Spring Cable management systems

Robotics solutions for thin or bonded wafers and specialized wafer carriers.

Laminated High Performance Flex Cables fit perfectly for this application.

- Class 1 Cleanroom ready and allows for multiple axis points and tight space requirements

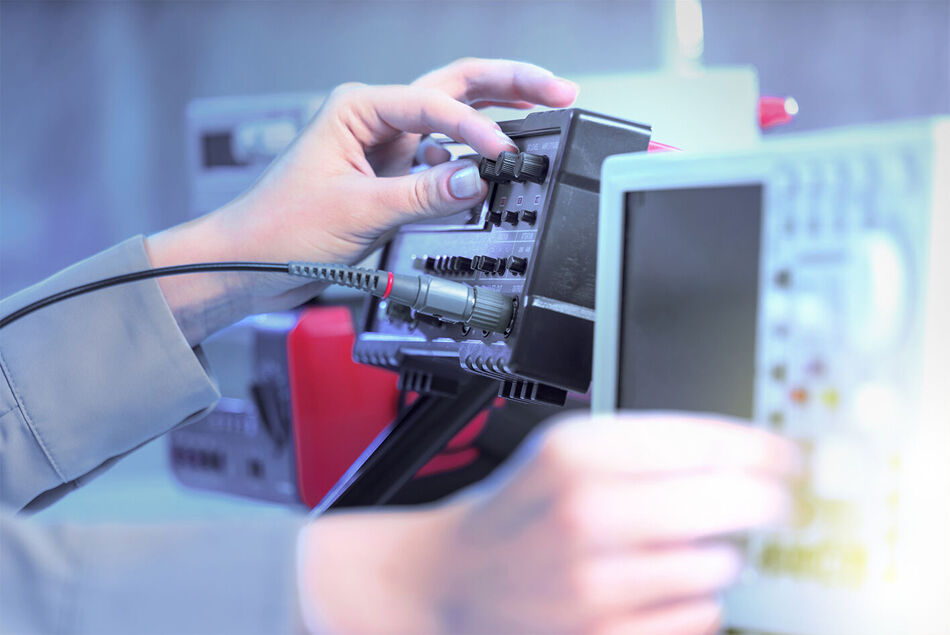

Flat Panel Displays

- Flexible Sleeve Technology (FST) Cables and High Performance Flex (HPF) Cables

- Provide the best cable solution for highly sensitive ESD equipment

- Lens manufacturing, Optical inspection equipment for large Flat Panel Displays,

- Test cell and inspection equipment and production equipment, e.g., laser glass cutting, are just some examples in these market fields.

Etching Equipment

- Allows for installation in tight spaces and the lowest industry standard in outgassing

- Typical applications are front-end etching equipment.

- Laminated High Performance Flex Cables enable faster, more complex, and more precise etching equipment with a smaller footprint.

- Leading SMT machinery manufacturers and leading semiconductor companies trust BizLink elocab cleanroom cables.

Overview of Custom Cables and Cable Assemblies

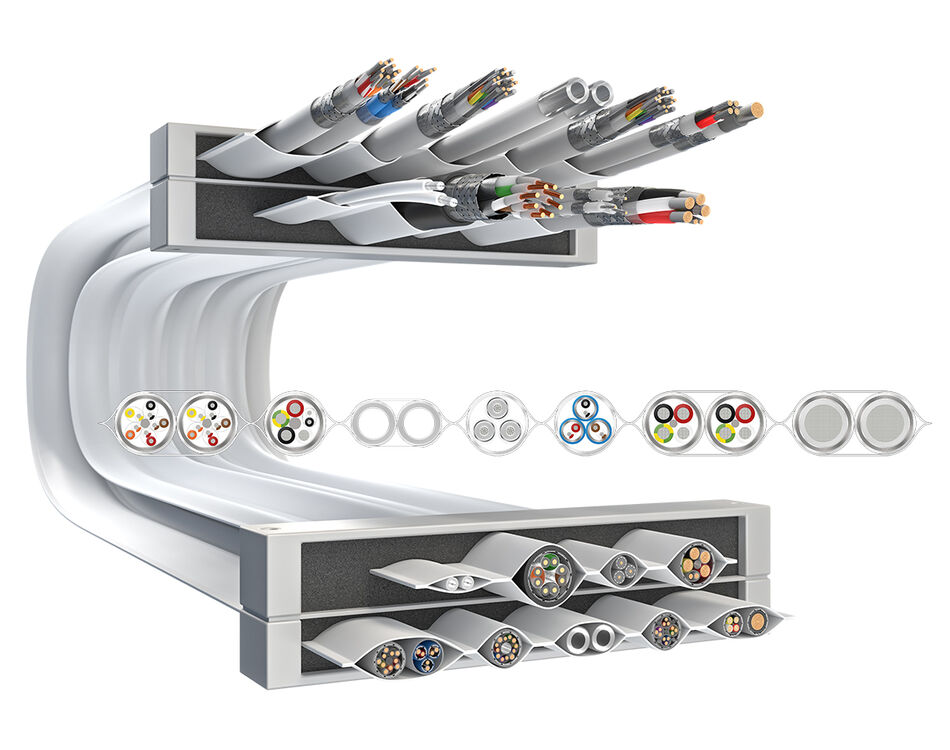

High Performance Flex Cable

- HPF Cables can be designed to exceed 150 million flex cyclesat tight bend radii

- Flexible components such as single wires, twisted pairs and optical fibers & tubes

- Maximum flexibility, optimized low friction and ultra-low particulation

- ISO class 1 cleanroom

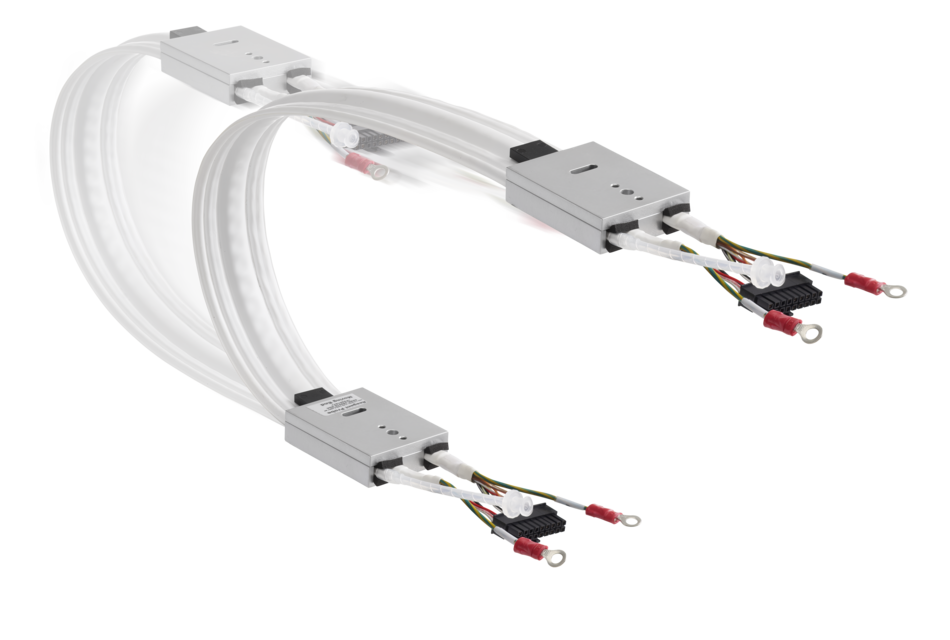

Robotic Arm Joints & Clock Spring

- Replacement of torsion-optimized round cable with high-performance flex cable

- Robot arm joint design for multi-axis movement

- Allows extended degrees of rotational freedom

- Tight routing of cable components utilized in a vacuum environment

Flexible Sleeve Technology (FST)

- Up to 10 million flex cycles at tight bend radii

- Flexible components such as stranded wires, twisted pairs, coaxial cables, data cables and fiber optics

- Maximum flexibility, optimized low friction, and ultra-low particulation

- ISO Class 1 cleanroom and Self-supporting features

Differentiators of Custom Semiconductor Cables

Experience with Difficult Projects

- Partner with a history of Solving problems for complex applications

Services Available for Custom Semiconductor Cables

Technical Capabilities

- Complete assembly solutions

- Strip & crimp AWG50 to AWG12

- Injection overmold capabilities

- Soldered & bolted connections, heat shrinking, potting

Testing & Quality Assurance

- Pin assignment

- Electrical continuity

- Insulation test for high voltage

- Custom test requirements available upon request

Your Benefits

- Rapid prototyping

- State-of-the-art equipment & machinery

- 360 Quality management system

- Full-service cable system engineering solution intONE™