Mining Cable Solutions

Tackling the toughest of cable challenges

Custom Cables for Miners, Shuttle Cars, Laser Welding and Other Mining Applications

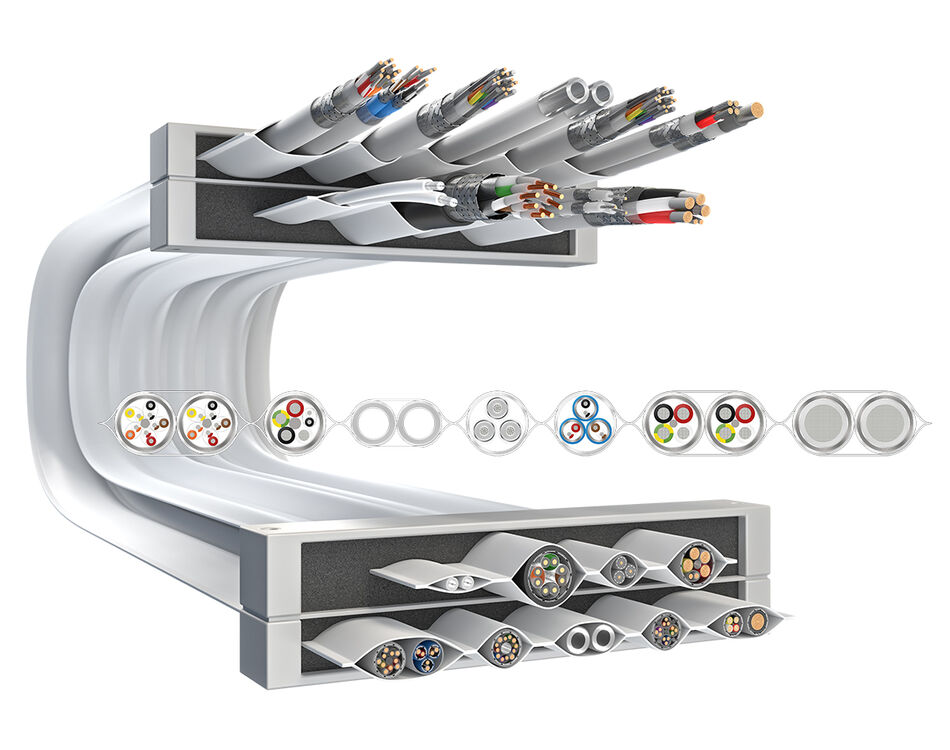

Durability is critical in the mining industry. Wire and cable must withstand the harsh conditions of impact, vibration, tension, and other hazards. Choosing high-quality mining cables and assemblies that effectively protect against these environmental dangers is essential. BizLink elocab offers custom cables and assemblies specifically designed to perform in these challenging conditions.

Located in the Toronto-Waterloo Tech corridor, BizLink elocab provides:

- State-of-the-art production capabilities.

- Exceptional technical support.

- Top of the line Customer service.

- Fast international shipping.

- Competitive pricing.

Our commitment to safety means we only produce rigorously tested, custom-made mining cables that meet or exceed stringent standards such as UL, CSA, or CE. With our custom-engineered cables, you can trust that your mining equipment will operate safely and efficiently. We are excited to serve you and help you find the best solution for your next challenging project.

Applications for Mining Cable Solutions

Overview of Mining Cable Solutions

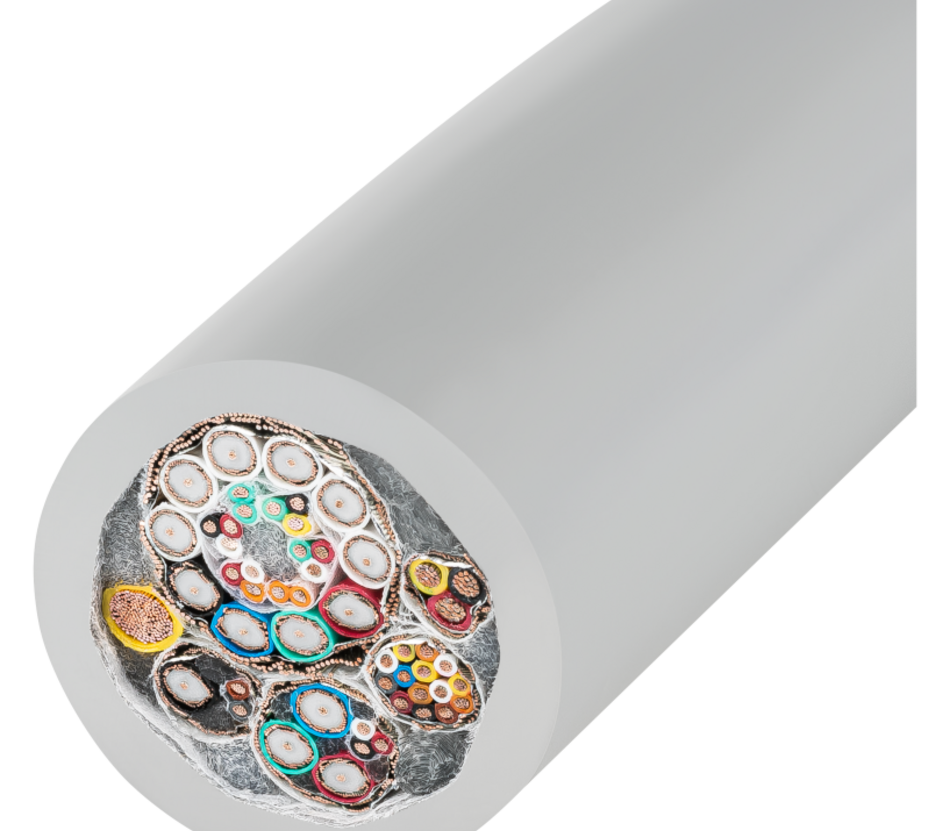

Hybrid Round Cables

- Complex component and cable designs

- Can include data, signal, power, tubes

- Low susceptibility to interference

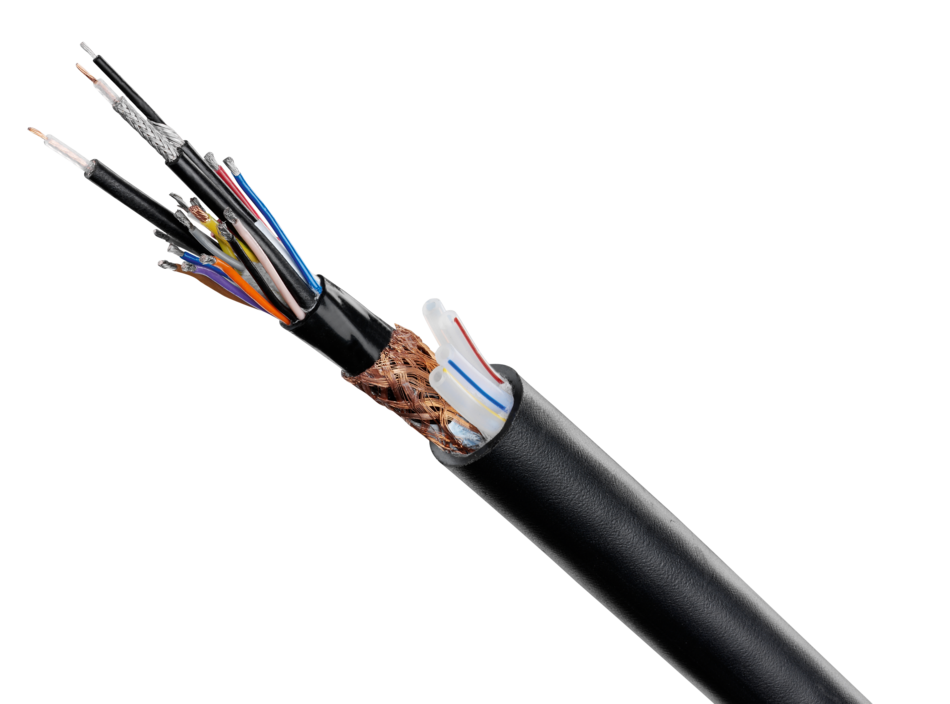

Custom Round Cable

- Tin and Bare Copper Conductor

- Advanced Jacket Materials

- Different Braiding Types with Protective Tape

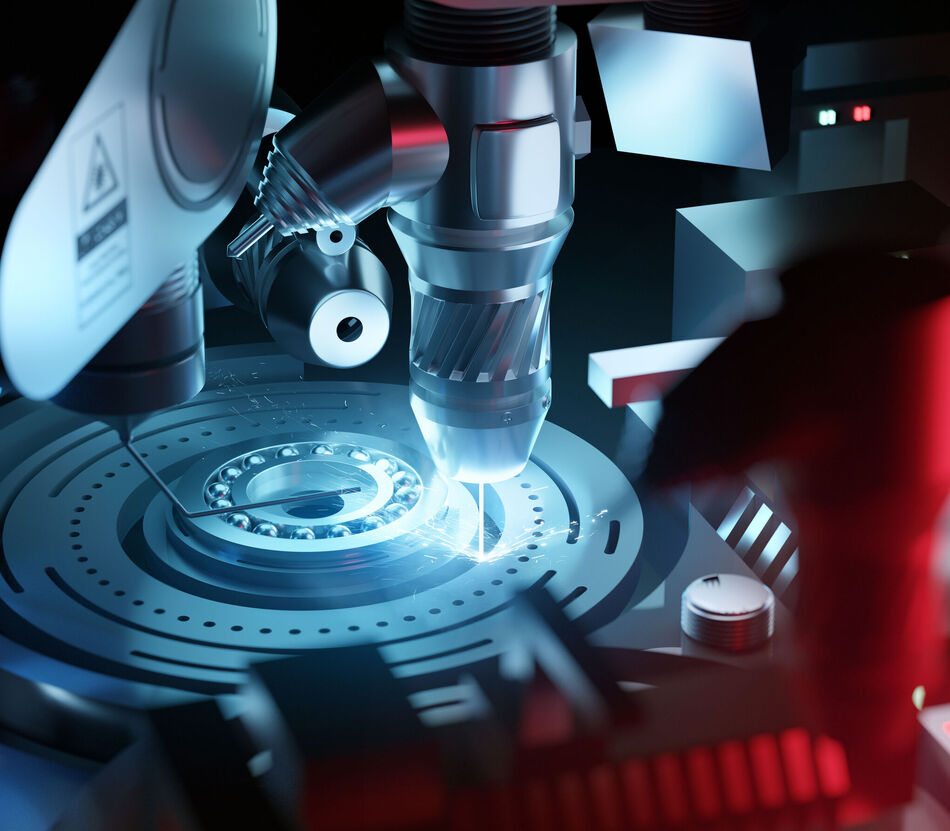

Welding Cables

- Manual welding guns

- Hybrid welding

- Deep welding

Differentiators of Custom Cables

Experience with Difficult Projects

Partner with a history of Solving problems for complex applications

Services Available for Custom Cables

Technical Capabilities

- Complete assembly solutions

- Strip & crimp AWG50 to AWG12

- Injection overmold capabilities

- Soldered & bolted connections, heat shrinking, potting

Testing & Quality Assurance

- Pin assignment

- Electrical continuity

- Insulation test for high voltage

- Custom test requirements available upon request

Your Benefits

- Rapid prototyping

- State-of-the-art equipment & machinery

- 360 Quality management system

- Full-service cable system engineering solution intONE™