Custom Cables for Pick and Place Applications

BizLink Custom-Engineered Pick and Place Cables

Custom Cable Solution for your Pick and Place Application

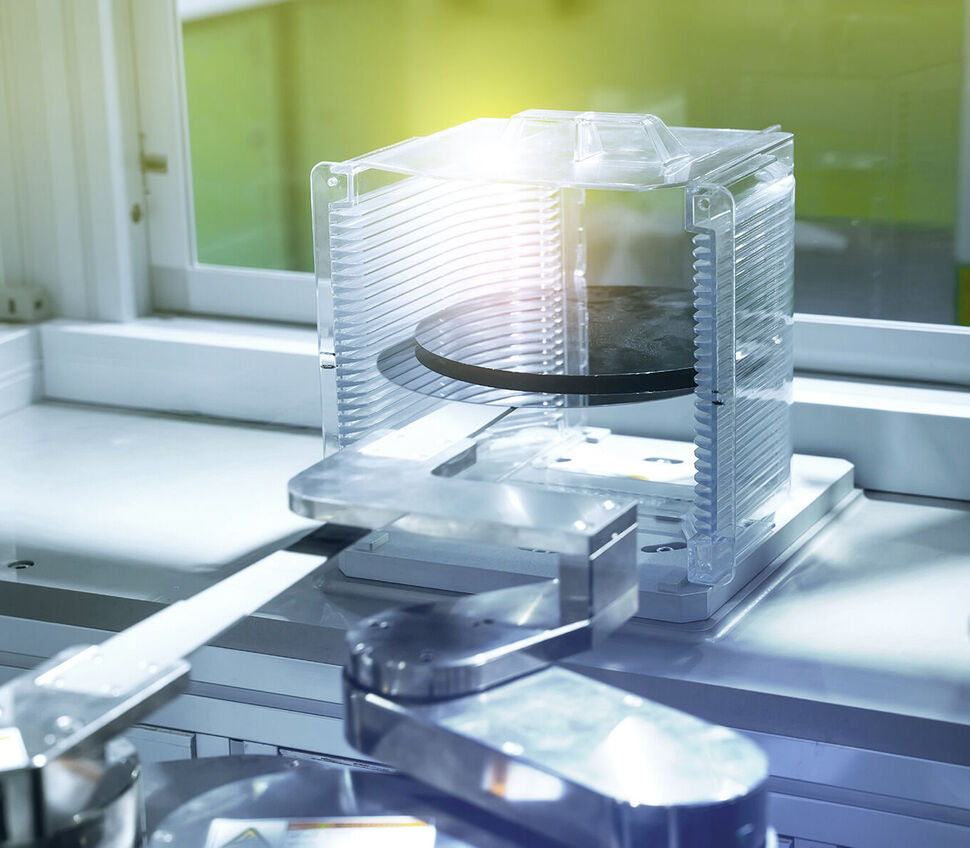

For dispensing and pick-and-place production machines, our drag-free PTFE cable solutions transport the adhesive or injection molding substrate to dies and PCBs, in addition to the important power and data lines. Approved for Class 1 air cleanliness, our solutions are perfect for the growing cleanliness standards in semiconductor and display production. Leading suppliers of highly flexible SMT assembly solutions with sophisticated dispensing systems rely on elocab's customized High Performance Flex Cables.

Our electrical and mechanical engineers design and manufacture custom cables that meet your stringent pick and place application requirements. Our High Performance Flex (HPF) Cables master the combination of electrical components and media hoses, are space-saving, absolutely abrasion-free and highly flexible.

BizLink provides exceptional technical support, customer service, fast international shipping, and competitive pricing. Our commitment to safety means we only produce rigorously tested cables that meet or exceed industry standards such as UL, CSA, and CE.

With our custom-engineered cables, you can trust that your application will operate safely and efficiently. We are excited to serve you and help you find the best solution for your next project.

Applications for Pick and Place systems

Overview of Custom Cables and Cable Assemblies

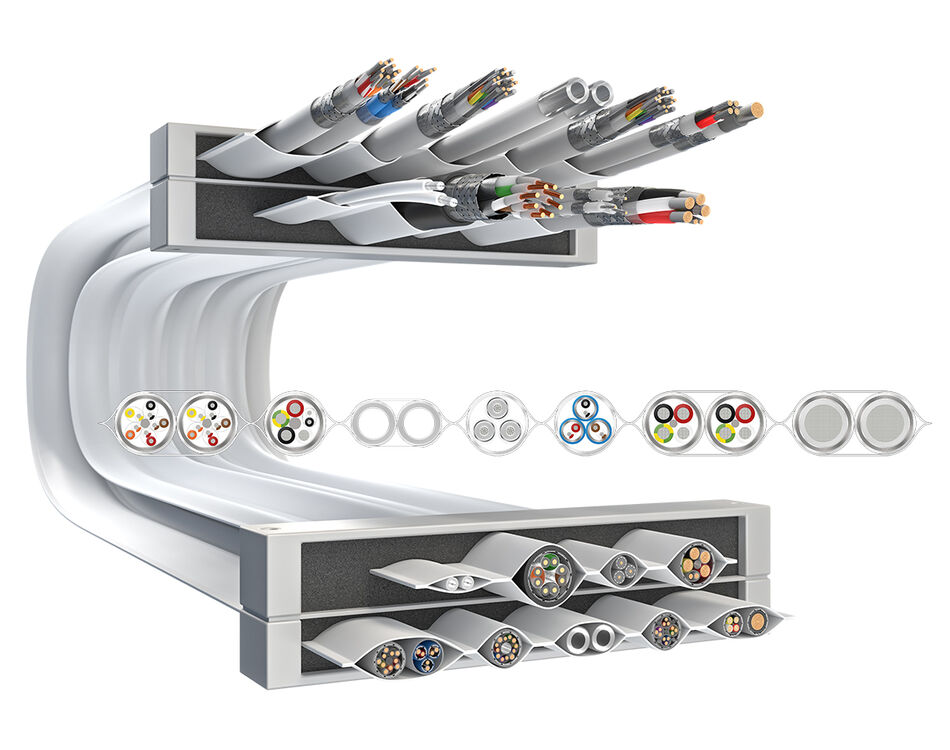

High Performance Flex Cable

- HPF Cables can be designed to exceed 150 million flex cyclesat tight bend radii

- Flexible components such as single wires, twisted pairs and optical fibers & tubes

- Maximum flexibility, optimized low friction and ultra-low particulation

- ISO class 1 cleanroom

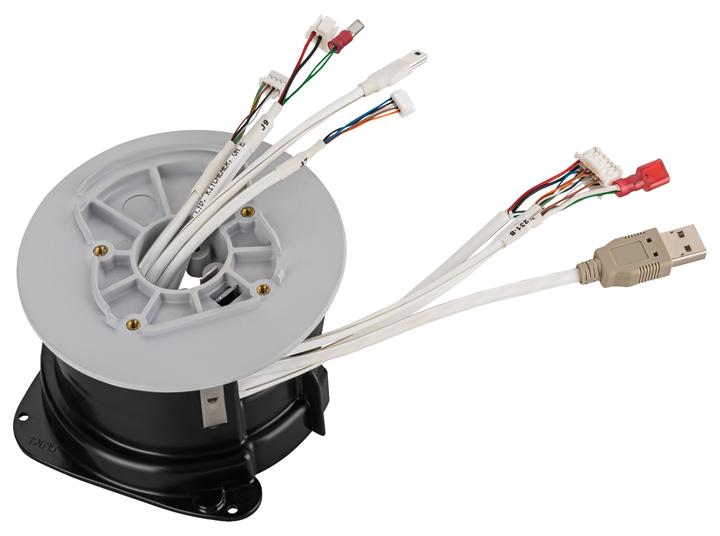

Robotic Arm Joints & Clock Spring

- Replacement of torsion-optimized round cable with high-performance flex cable

- Robot arm joint design for multi-axis movement

- Allows extended degrees of rotational freedom

- Tight routing of cable components utilized in a vacuum environment

Flexible Sleeve Technology (FST)

- Up to 10 million flex cycles at tight bend radii

- Flexible components such as stranded wires, twisted pairs, coaxial cables, data cables and fiber optics

- Maximum flexibility, optimized low friction, and ultra-low particulation

- ISO Class 1 cleanroom and Self-supporting features

Differentiators of Pick and Place Cables

Experience with Difficult Projects

Partner with a history of solving problems for complex applications

Services Available from BizLink elocab

Technical Capabilities

- Complete assembly solutions

- Strip & crimp AWG50 to AWG12

- Injection overmold capabilities

- Soldered & bolted connections, heat shrinking, potting

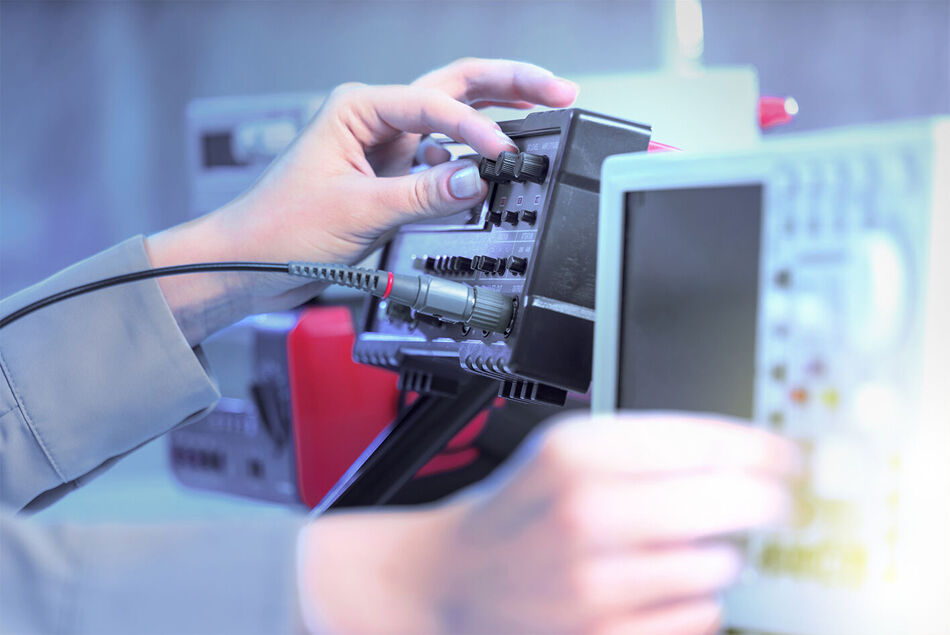

Testing & Quality Assurance

- Pin assignment

- Electrical continuity

- Insulation test for high voltage

- Custom test requirements available upon request

Your Benefits

- Rapid prototyping

- State-of-the-art equipment & machinery

- 360 Quality management system

- Full-service cable system engineering solution intONE™