Robotic and High Flex Automation

To request a quote for Custom Robotic and High Flex Automation Cables, call +1 866-356-2221 or email bca_sales(ät)bizlinktech.com

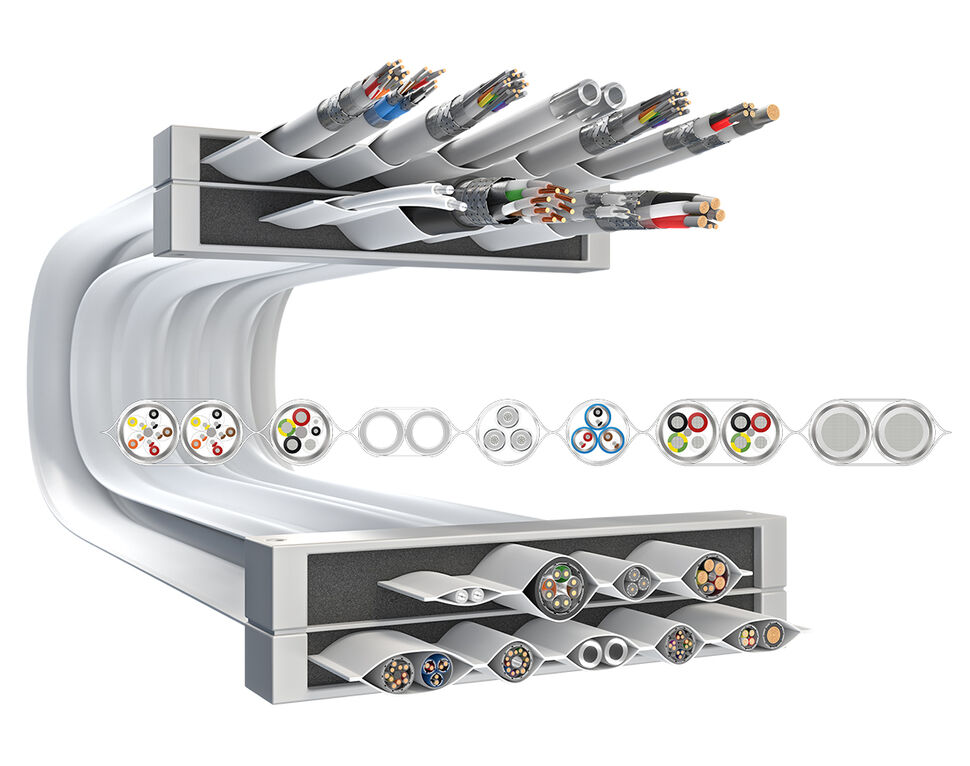

BizLink understands the need to have a small footprint while meeting high electrical requirements. Lower your preventative maintenance costs with a custom cable that supports up to 150 million flex cycles.

Why use a tailor-made cable for robotics & high flex automation

BizLink supports robotics applications that require a tighter bend radius and perform under torsion in a clockspring motion. Our custom High performance flat and custom round cables made in North America are available in complete assemblies and have proven to meet our customers biggest challenges.

Custom Automation Cables

- Linear drives

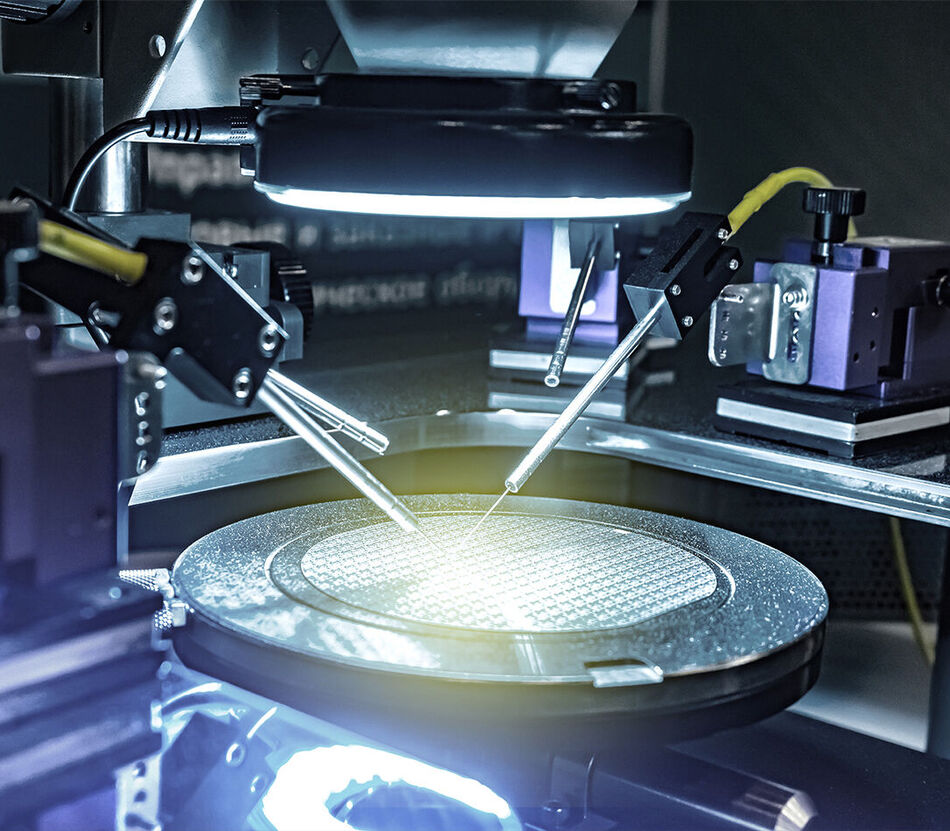

- Semiconductor applications

- Clean room cable systems

- and much more

Custom Surgical Robotic Cables

- Computer-assisted surgery (CAS)

- Monitoring / information systems

- Electro surgical systems

- and much more

How our cables make a difference

BizLink brings unique values to each custom designed robotic and high flex automation cable and cable assembly.

Unbreakable cables

Our cables withstand up to 150 million flex cycles avoiding equipment downtime.

Learn more

Continuous motion flex

Our automation & robotic cables resist complex, repeated bending movements.

Learn more

Torsional high flex

Our custom flat cable allows twisting along its axis. Tension stressing as well as cable bending may occur in this situation.

Learn more

Technical Capabilities

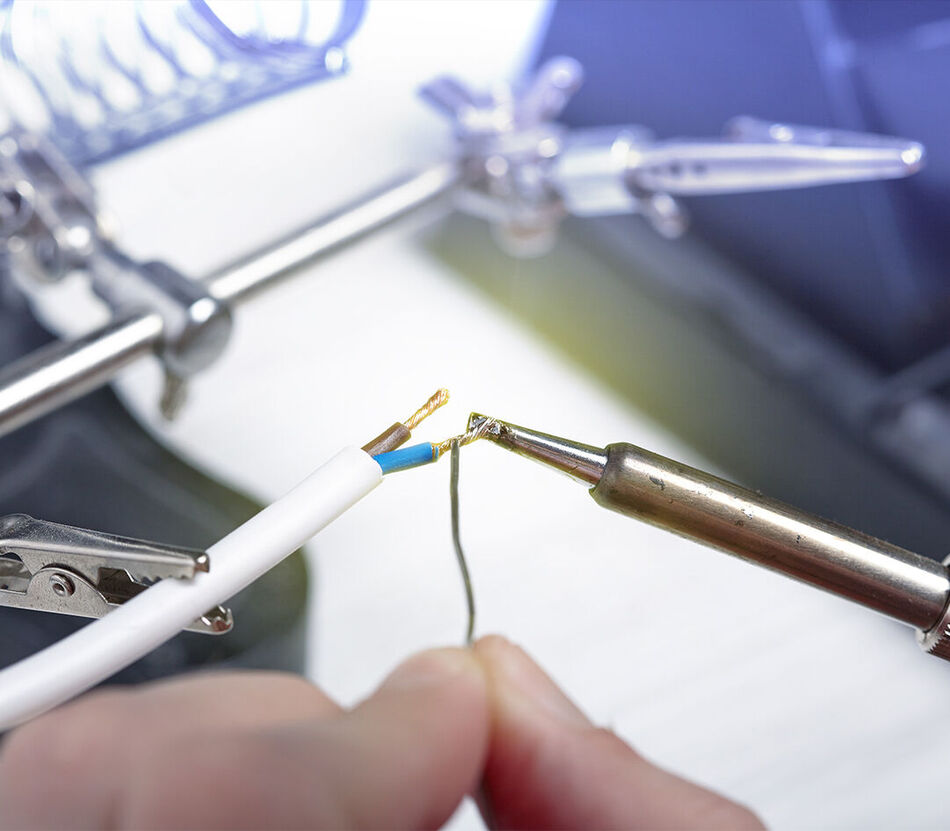

- Strip & crimp AWG50 to AWG12

- Injection overmold capabilities

- Soldered & bolted connections, heat shrinking, potting and more

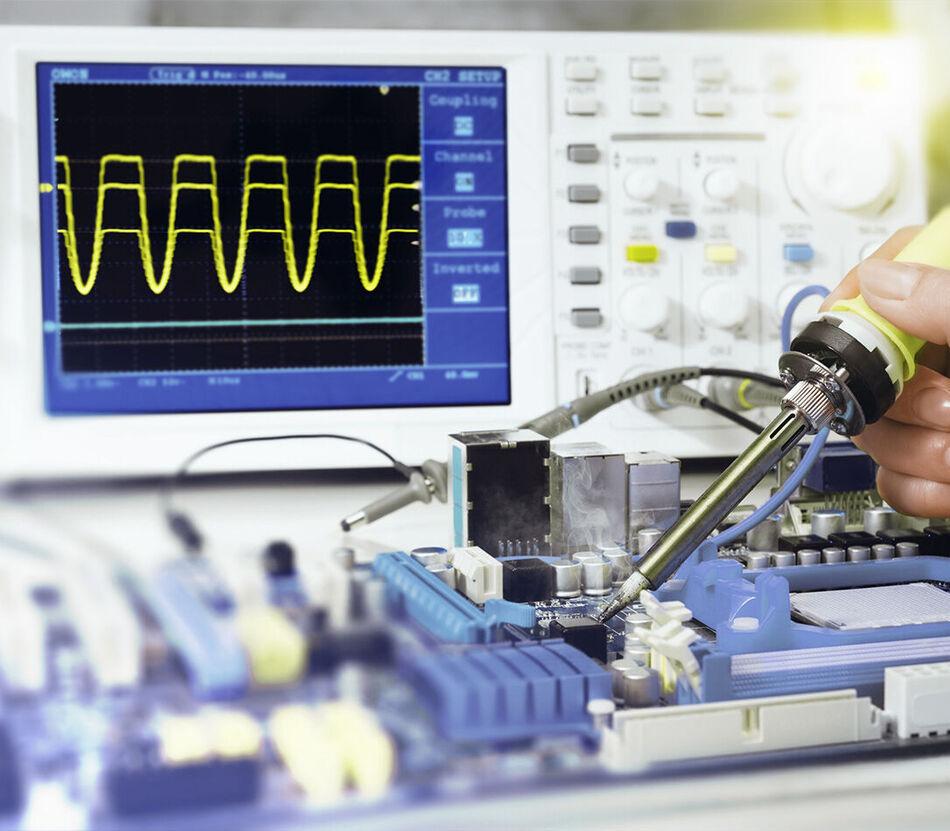

Testing & Quality Assurance

- Pin assignment

- Electrical continuity

- Insulation test for high voltage

- Custom cables test requirements available upon request

Your Benefits

- Rapid prototyping using aluminum inserts

- State of the art equipment & machinery

- 360 Quality management system

- Full service cable system engineering solution intONE™